Modern Machine Shop, Edited by Jedd Cole, Assistant Editor from Modern Machine Shop

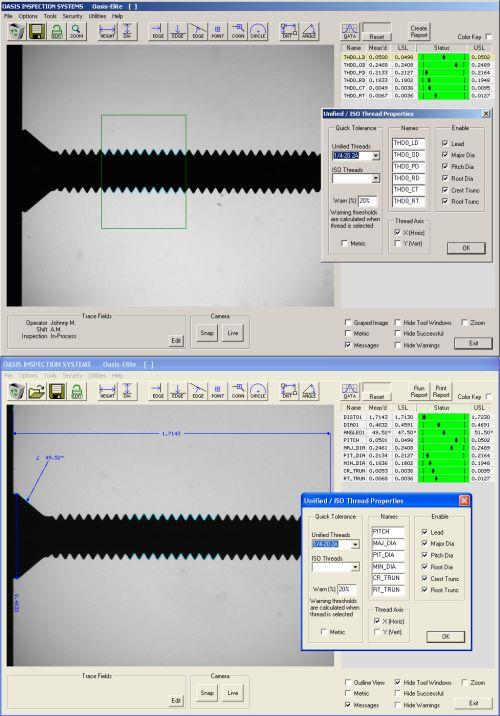

The OASIS offers a thread measurement add-on to its OASIS Inspection System, which instantly and simultaneously measures external dimensions on profile views of parts. The software’s thread tool measures key components of thread geometry in less than a second, says the company, including major, minor and pitch diameters. Pitch distance as well as crest and root truncation are also included. The thread tool also works on 60-degree, V-form straight threads, and tolerances can be individually set for each characteristic measured. Other capabilities include threaded part sorting and thread identification in large batches. Inspection is said to achieve accuracies to ±0.0001″.

In operation, the inspected parameters display on the system monitor, which graphically shows the status of every component in traffic light colors: green indicates within tolerance, yellow indicates close to limits and red indicates out of tolerance. Dimensions can be saved in the inspection report spreadsheet or imported in real time to SPC (statistical process control). Alternatively, the thread tool suits in-process thread production monitoring.